Our aim is to provide an all-in-one solution for our partners in composite production.

about us

WE CREATE

COMPOSITE

STRUCTURES

Advanced Composite

Structure Manufacturing

The company offers “all in one” solution to potential partners, from engineering and development to production and assembly. In addition to producing its own products, thanks to an accurate analysis of customer needs and the quality of delivered products, Magnus Aircraft Zrt. is becoming a qualified supplier of composite structures. Advanced composite industry, which is a specific sector of the composite industry, is characterized by using high-performance resin systems and high-strength, ultra-stiff fiber reinforcement.

Quality

INFRASTRUCTURE AND MANUFACTURING CAPABILITIES

In terms of engineering and production, the technology available to Magnus Aircraft Zrt. encourages the development of monolithic structures and sandwich designs, featuring a high degree of component integration and complex shapes.

The manufacturing activity production plant of Magnus Aircraft Zrt. is divided into the following production segments: preparation and lamination area, cutting and trimming room, painting and finishing area and assembly area.

The manufacturing activity production plant of Magnus Aircraft Zrt. is divided into the following production segments: preparation and lamination area, cutting and trimming room, painting and finishing area and assembly area.

Quality

KNOW HOW

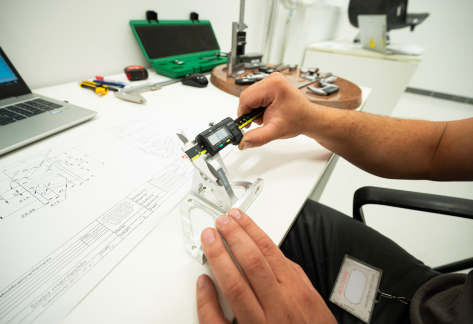

Magnus Aircraft’s manufacturing know-how of advanced composite structures includes manufacturing technology, development and production engineering, tool design and manufacturing, detailed production of components and integration of fittings. Production is supported by composite oriented production planning, tracking and control.

Quality

Comprehensive Quality Assurance

At Magnus Aircraft Zrt., quality is at the forefront of our operations, and our commitment to excellence is reflected in every aspect of our production and development processes. We have established detailed work instructions for producing composite elements and assembled components, covering specifications for the composite substructure, base and auxiliary materials, tool preparation, and gelcoat application.

Quality

Supplier and Subcontractor Evaluation

We conduct annual evaluations of our suppliers based on key criteria such as quality, delivery accuracy, communication, and documentation adequacy. Our subcontractors are audited annually to comply with ISO 9001 standards and Part21 regulations, ensuring that every component meets our quality expectations.

We have a dedicated test bench for stress testing components. For design verification, we collaborate with Econ Engineering Kft., leveraging their expertise in simulating composite structures through finite element analysis (FEM).

Quality

Certifications and Compliance

We are working towards acquiring Production Organization Approval under EU Regulation 748/2012, which will enhance our capability to produce light aircraft and components with formal certification. Additionally, we are pursuing certifications such as AQAP 2110 / 2120 / 2130 and AS/EN 9100, positioning us as a qualified supplier in the defense and aerospace sectors.

for example

REFERENCES

Magnus Aircraft product line includes aircraft products, advanced composites and water sports equipment. Currently, Magnus manufactures aircraft composite elements for its own Fusion family, Fusion 212 and Fusion 213.

Besides it, we are producing yacht composite frames, kayaks, truck bodies, car bumpers.